23 May 10 Proven Methods to Increase Warehouse Efficiency and Cut Costs

10 Proven Methods to Increase Warehouse Efficiency and Cut Costs

The foundation of any effective supply chain is the warehouses and distribution facilities. Effective warehouse management and operation can help you save expenses significantly, increase production, and shorten lead times. However, if a warehouse is not operating to its maximum potential, it could cause delays, higher costs, and lost business opportunities.

In this blog, we will discuss the top 10 ways that will help you improve warehouse efficiency, reduce costs and increase profitability. Warehouse managers all around the world have used these tried-and-true methods since they have been demonstrated in the industry.

1. Organize and Label Your Inventory:

To keep everything in order, begin by organizing your items and distinctly labeling everything with shelving, racking, and other storage solutions. To make it simple to find products and to maximize worker mobility inside the warehouse, utilize a systematic arrangement. Keep your often utilized things close to the shipping dock and your less frequently used items close to the facility’s back.

2. Implement an Effective Fleet Management System & Warehouse Management System (WMS):

You may assess and optimize depending on the data that effective fleet management systems give you in real-time for your entire fleet. You can track shipping, keep track of your inventory, and analyze consumer data with the aid of a reliable WMS to help you make smart purchase decisions. The WMS and fleet management system you choose should be simple to use, scalable, and simple to interface with other programs.

3. Adopt Lean Principles:

Lean practices emphasize minimizing waste and improving warehouse flow. Putting lean principles into practice can help you clear out clutter, save time, and cut costs. Use strategies like 5S, value stream mapping, and visual management to streamline your operations.

4. Optimize Your Warehouse Layout:

How your warehouse is set up will affect how quickly your workers can navigate it. A well-designed warehouse layout can reduce travel time, increase pick rates, and improve accuracy. Before choosing a layout, test out various options using computer simulations. To maximize the usage of your warehouse, Atlantic Handling Systems offers specialized warehouse designs and layouts.

5. Invest in Automation:

Your workforce can perform more high-value jobs if repetitive, laborious chores are automated. For more productivity, give automated storage systems, robotics, and automatic guided vehicles a look at your warehouse operations.

6. Implement a Continuous Improvement Program:

Encourage your staff to contribute ideas and suggestions for improving warehouse processes. By fostering a culture of continuous improvement and opportunities, you can innovate and stay ahead of the curve.

7. Provide Ongoing Training:

Ensure that your staff knows the correct way to use equipment, follow procedures and communicate effectively. Ongoing training can help them become more productive, efficient, and confident in their work.

8. Use Barcoding and RFID Technology:

Implementing barcoding and RFID technology can help you receive, put away and pick products more efficiently. This technology can also assist with inventory management and tracking.

9. Establish Key Performance Indicators (KPIs):

Establishing KPIs can help you set goals, monitor performance, and identify areas for improvement. Track metrics like inventory accuracy, order fulfillment rates, and shipping lead time to keep tabs on your progress. When using fleet management systems allows you to view the real-time data of your fleet helping you better track and manage the KPIs that matter most to your operation.

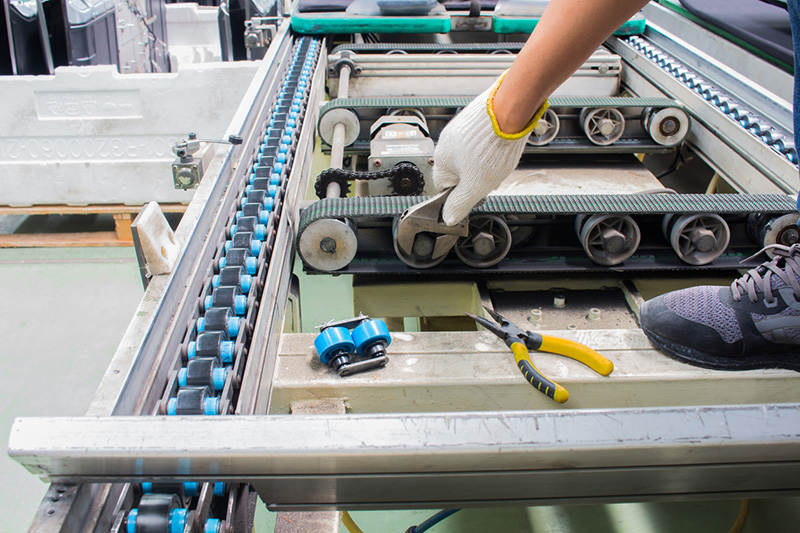

10. Maintaining Your Equipment:

Although it may seem easy enough, maintenance on some equipment is frequently disregarded. Implementing a maintenance program or system can ensure that your warehouse can operate at its maximum potential and that less time and money are lost due to equipment issues. All material handling equipment is serviced and maintained by Atlantic Handling Systems. Conveyors, vertical lifts, wire partitions, pallet racks, and shelving, among other material handling equipment, are among the items we service. To find out more about our service & full maintenance programs, get in touch with our team today.

Although running a warehouse is no easy endeavor, using these 10 tactics can result in considerable cost reductions and efficiency gains. You can make your staff’s jobs easier, safer, and more precise by keeping your inventory organized, maintaining your machinery, and spending money on automation. It’s crucial to keep in mind that these approaches are not a one-and-done fix. To maximize operations and maintain an edge over the competition, it’s critical to regularly examine, modify, and tweak your procedures.

Sorry, the comment form is closed at this time.