Systems

Custom designed projects where the details fit your exact specifications.

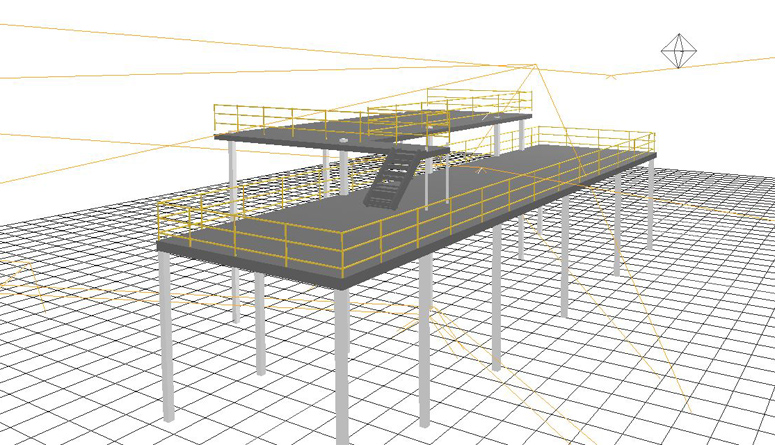

Atlantic Handling Systems Engineering Department reviews all but the simplest projects to assess the additional value that Atlantic can furnish. We frequently provide customization of standard products to create a better solution for a specific customer application. Atlantic’s Systems Designer is Factory-Trained and utilizes AutoCAD, the latest in engineering software, to design, layout and alter drawings. This enables you to play a major role in the systems design process.

Install

Exceptional customer service which includes an average 95% customer rating

Atlantic Handling’s Installers work to thoroughly understand your facility, processes and product profiles. Atlantic has a fleet of service vans that cover all of Tri-State Area. Our knowledgeable Installers are factory-trained and have over 60 years of combined installation experience on all of the products that we sell. Work safety is a priority at Atlantic. All of our Installers attend safety training seminars, which not only ensures their own safety, but also the safety of our customers’ employees.

We are proud to be an authorized Modula dealer

Modula Vertical Lift Modules (VLMs) are fully automated vertical storage systems that take up a minimum footprint by utilizing the ceiling height available. These systems allow for large inventory of goods to be quickly accessible while being stored in a safe and secure environment and automatically delivered to the operators, with a simple touch on the user friendly Copilot controller or the scan of the barcode.

Organize and secure your business with WireCrafters

WireCrafters specialize in wire partitions and cages. The most common uses for wire partitions and cages are warehouses, distribution centers, and manufacturing facilities commonly use wire partitions for tool cribs, maintenance cages, machine guarding, and general inventory storage areas. Wire partitions and cages are also utilized in data centers to secure servers and by law enforcement for temporary holding cells and evidence storage.